Botou Shitong Cold Roll Forming Machinery Manufacturing Co., Ltd.

was established in 2001. Our company is a comprehensive enterprise

integrating production, sales and services. We are mainly devoted

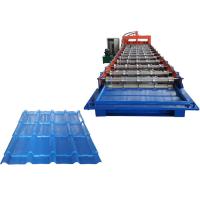

to the development and manufacturing of metal plate cold bending

roll forming equipment.

We have high quality professional teams, skillful talents,strong

technical force,strong and independent research and development

capabilities, advanced production equipment and a perfect

after-sales service system.

We have great confidence in the quality and precision of our

products. Our customers feedback said that it is a great machine,

no noise, clean, very advanced technology. And it also has the

features of light structure and reasonable design.

We manufacture wide range products of metal sheet cold roll forming

machine as follows: color steel roll forming machine, glazed tile

roll forming machine, C/Z/U purlin machine for light steel

structure building, floor deck machine, sandwich panel production

line, fast guardrail forming machine, ridge cap forming machine and

other automatic cold bending roll forming equipment. Our export

team will listen to your request; the designed team will show you

the best proposal according to your request, and we also have

experts skilled workers offer precision work. Satisfactory

solutions were provided to customers and established a long-term

strategic partnership.

We are one of the best roof and wall roll forming machine

manufacturers and suppliers in China. We have established a long

term business relationship with more than 26 countries. Such as

South America, North America, Asia, Southeast Asia,Africa, Europe ,

Australia and Middle East.

We are willing to promote the economic and technical exchanges with

the world and establish trade relations with friends from all over

the world. We firmly believe that a true partnership is built on

the basis of customers’ satisfaction.

Whatever you need or want, you will find it here. See for yourself.

Look through our E-Commerce site now and compare. I think you will

agree that these are excellent products at prices among the lowest

in the industry. I promise you that they will perform trouble-free,

over and over for years and years.